Time:2021-08-02

Read volume:666

Share:

With the improvement of people's living standards and quality of life, the requirements for the processing accuracy and aesthetic appearance of daily products are also very high. For products that cannot be molded at one time but have high air tightness requirements, the plastic welding process can reduce the designer's concern for Product design difficulty.

Compared with traditional vibration friction welding, ultrasonic welding, hot plate welding and other welding processes, plastic laser welding has obvious advantages. . Plastic laser welding technology has a broad potential market in automotive, medical, home appliances, electronic appliances and other industries.

Introduction of gas-liquid separator

With the implementation of the National VI Standard, the requirements for energy conservation and emission reduction of automobiles are higher. The gas-liquid separator is placed between the fuel tank and the activated carbon canister. The gas-liquid separator can purify the exhaust gas produced by the fuel tank system, separate the gaseous gasoline and recycle it, thereby helping the automobile fuel tank system to save fuel and reduce emissions.

The temperature change in the fuel tank system causes the pressure in the fuel tank to change. During the cooling or pressurization of the saturated gas, a part of the condensable gas components will form small droplets and flow with the gas, which causes part of the gasoline in the fuel tank system to become gaseous. The gas-liquid separator intercepts the gaseous gasoline and returns it to the fuel tank, while the exhaust gas is sent to the activated carbon canister for filtration. Therefore, the gas-liquid separator achieves the purpose of saving fuel and protecting the environment.

Compared with traditional vibration friction welding, ultrasonic welding and hot plate welding, plastic laser welding has more process stability and can meet the production requirements of products. Therefore, gas-liquid separators have high requirements for safety and strength. The liquid separator adopts the plastic laser welding process.

Selection of Plastic Welding Process for Gas-liquid Separator

There are many methods for plastic laser welding, such as synchronous welding, quasi-simultaneous welding, contour welding, roll welding and irradiation mask welding. The previous articles have introduced these welding methods in detail, and will not be repeated here.

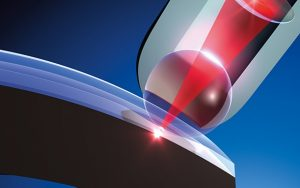

Globo ball welding is one way of rolling welding method. Globo welding is also called ball welding, which is welded along the contour of the product. The laser beam is focused on the welding contour line by an air-cushioned glass ball that can roll freely without friction, and heats the welding area to complete the welding.

GLOBO welding plastic welding can achieve high process stability and welding strength to ensure that the inside of the gas-liquid separator can withstand sufficient pressure.

Some parts in the shell of the gas-liquid separator have special welding points, so the welding of welding columns and welding ribs is difficult, and it is difficult for ordinary plastic welding to meet the requirements. The welding points and fork-shaped welding ribs are convex. The GLOBO welding process contacts the workpiece through the glass ball at the end of the lens. It is very convenient to apply welding pressure on these convex positions. At the same time, the lens transmits the welding energy to the welding point accurately. .

The outer edges, inner ribs and poles of the black lower shell of the gas-liquid separator need to be welded with the plastic cover plate. Due to the difference in the injection molding process and the deformation of the plastic parts, there will be a certain drop in the welding surface. Using a ball lens makes it easy to bridge these drops and provide even welding pressure during the welding process.

At present, plastic laser welding has mature application experience in the automotive field. In addition to the application in the gas-liquid separator of the automobile fuel system described above, plastic laser welding is also used in vehicle lights, instrument panels and other components of the fuel system. Plastic laser welding technology is of great strategic significance for the lightweight and cost reduction of automobiles, especially the transformation and upgrading of plastic parts manufacturing. Facing the demand market of automobile plastic welding, plastic laser welding technology has broad market prospects.

Huazhuo Technology, backed by the technology research and development system of Huazhong University of Science and Technology, is the first enterprise in China to produce and develop plastic laser welding technology, and also the first enterprise to create a plastic laser welding technology database. In the automotive, medical, lighting, packaging and other industries, it provides complete plastic laser welding process solutions.

2021.07.17

2021.07.03

2021.07.17

2021.07.17

2021.07.17

2021.07.17

2021.07.01

2021.07.03