Time:2021-07-17

Read volume:1014

Share:

Nowadays, consumers have higher and higher aesthetic requirements for the appearance design and overall shape of taillights. To create a taillight with a beautiful appearance poses a challenge to the welding process in the manufacturing process.

1Potential stocks in the car lamp welding industry - plastic laser welding

Hot plate welding is a welding technology with the earliest development and the simplest process in plastic welding technology. With the development of technology, at present, the most used welding methods in vehicle lamp manufacturing are vibration friction welding and ultrasonic welding. In addition to this, laser welding technology is receiving more and more attention.

From the comparison of several welding technologies in Table 1, it is not difficult to see that plastic laser welding has the characteristics of beautiful welding seam, flexible welding and high strength, and has become a "potential stock" in the welding technology of automobile lamps.

Table 1 Comparison of different welding processes

With the development of laser technology and the decrease of equipment cost, laser welding is becoming the mainstream process of car lamp welding. So, how adaptable are plastics to laser welding?

2Some plastics are not suitable for laser welding without modification

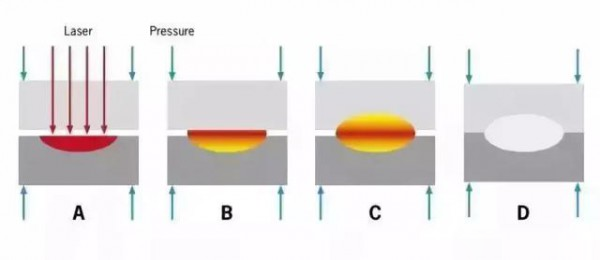

Laser welding is a welding method that uses a high-energy-density laser beam as a heat source, that is, laser radiation heats the surface of the workpiece, and the surface heat diffuses into the interior through heat conduction to melt the workpiece and form a specific molten pool. Therefore, the energy of the laser beam must be absorbed by the plastic in order to achieve good welding results (as shown in Figure 1).

Figure 1 Schematic diagram of laser welding process

Therefore, the plastic must have special optical properties in the near-infrared region to be suitable for the laser welding process. The upper transparent layer needs to ensure that the near-infrared laser is transmitted, and the lower absorbing layer must ensure that the near-infrared light is absorbed. So, what are the optical properties of the plastic itself?

In terms of polymer morphology, amorphous polymers absorb only a small amount of incident light and can achieve high penetration depths.

Picture 4.png schematic diagram of light welding process

Figure 2 Spectra of four polymers (without additives)

As shown in Figure 2, the four amorphous polymers exhibit high transmittance in both visible and near-infrared regions. Due to the existence of the crystalline region, the optical properties of the crystalline polymer are quite different, the laser is refracted or reflected at the interface of the spherulite region, the travel through the material is longer, and the absorption rate of the laser is higher than that of the amorphous polymer.

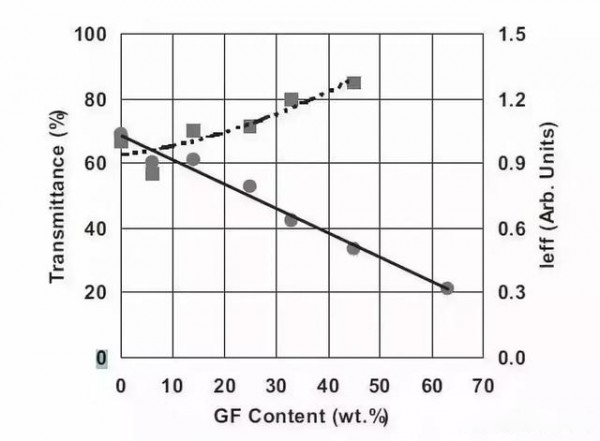

For filled polymer materials, the optical properties are greatly affected by the filler material. Taking glass fiber as an example, Val Kagan studied the transmittance of PA6 reinforced resin with different glass fiber content (Figure 3), and found that with the increase of glass fiber content, the transmittance of the material decreased linearly.

Figure 3 The effect of glass fiber content on the transmittance and optical path length of PA6 (leff: effective optical path length, 0% glass fiber is normalized)

3Choice of laser welding process

As the requirements for design aesthetics are getting higher and higher, the requirements of the laser welding process for the welding materials are becoming more and more complicated. In addition to the common transparent-black product welding, there are even black-black products, transparent-transparent products, white products - Other needs such as white products. In the selection of laser welding process, too high laser power or too long welding time will easily lead to excessive melting of materials and cause degradation. In order to achieve ideal welding quality, appropriate laser power, scanning speed and welding time should be selected.

Different from the traditional plastic welding process, laser welding uses laser radiation energy to weld two polymers, which not only has a wide range of applicability in polymer selection, but also has the characteristics of beautiful welding seam, flexible welding and high welding strength. At the same time, plastic laser welding puts forward special requirements for material properties - selective absorption and transmission of laser light. In order to obtain satisfactory parts, it is not only necessary to adjust the welding process parameters, but also the selection of suitable materials is very important!

2021.07.03

2021.07.17

2021.07.17

2021.07.01

2021.07.17

2021.07.17

2021.07.03

2021.08.02