Time:2021-07-01

Read volume:610

Share:

The processing technology of automotive interior parts has made great progress in the past two years, and the details of various interior parts including instrument panels, doors, seats, etc. have become more and more refined.

The traditional instrument panels are welded by vibration friction plastic welding. The high-frequency vibration during the welding process will scratch the surface of the instrument panel. Therefore, the vibration friction welding fixture needs to be covered with soft materials to prevent the welding process from affecting the instrument panel. scratches on the surface. Another small problem of vibration friction welding is that the welding process produces welding slag, and the cleanliness is not good. For instrument panel welding, the biggest problem with vibration friction welding is that there will be a lot of glue overflow after welding, and the welding line or welding area is very unsightly. The traditional practice is to hide these welding lines. However, with the continuous compactness of automobile interior design, the space left for plastic welding design has become smaller and smaller. In many cases, the welding seam of the instrument panel is completely exposed in the visible range. Therefore, the search for a new aesthetic plastic welding process has become a real need.

Advantages of laser plastic welding:

1. There is no vibration during welding. Plastic laser welding is a non-contact welding method. The upper and lower workpieces are stationary after being clamped by the fixture, and there is no relative displacement during the welding process. Therefore, the plastic laser welding process is particularly easy to protect the appearance of the product.

2. There is almost no flash, and the welding line has a beautiful appearance. The welding line formed by plastic laser welding is very beautiful and can be directly used as the appearance surface. In the process of laser welding, like vibration friction welding, there will be a lot of overflow in the welding area due to the massive collapse of the welding ribs, and the welding line will be very ugly. This is also the main reason for the use of laser welding for interior and exterior trims of automobiles.

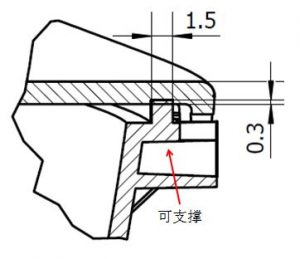

Difficulties of instrument panel laser plastic welding: The first difficulty of instrument panel plastic laser welding process is design. If laser welding is used for plastic products, product design must be carried out according to the design requirements of the selected laser plastic welding process. For the laser welding design of the instrument panel, the most important thing is the design of the welding ribs. In the process of plastic laser welding, the welding ribs must have sufficient welding pressure, and this welding pressure is obtained by applying pressure to the fixture. Therefore, when designing the welding rib for plastic laser welding of the instrument panel, it is necessary to ensure that there is enough space under the welding line for the fixture, and the fixture must be able to fully support the welding line (refer to the figure below).

In addition to the difficulty of welding line design, the deformation of injection molded parts is also a stimulus to the plastic of the instrument panel.

A relatively big difficulty in light welding. The size of the instrument panel is generally large, so there will definitely be deformation during injection molding. The lower housing material is generally PC/ABS material, the upper lens is PMMA material, and PMMA is a fragile material. If the welding pressure applied during the laser plastic welding process is too large, the upper shell of PMMA is likely to be fracturing or crushing. broken. The lower housing is generally a high-wall structure with a thin wall thickness but a high height. Such a structure is prone to bending deformation under pressure, resulting in welding defects.

In order to cope with the deformation of the injection molded workpiece of the instrument panel, an adjustable mechanism must be designed when designing the laser plastic welding fixture, and an adjustment block must be designed in the area that is prone to deformation and stress concentration to ensure that the fixture can be adjusted during subsequent process debugging.

In addition to designing flexible fixtures, finding an accurate process window is also an important factor in the successful development of the instrument panel laser welding process during the process development process of instrument panel laser plastic welding. In the process of finding process parameters, for high-wall products such as instrument panels, generally too much welding pressure cannot be used, otherwise, under the action of a large welding pressure, the deformation of the workpiece will increase, which is more likely to cause plastic laser welding. welding defects.

2021.07.17

2021.08.02

2021.07.17

2021.07.03

2021.07.03

2021.07.17

2021.07.17

2021.07.17