Time:2021-07-01

Read volume:535

Share:

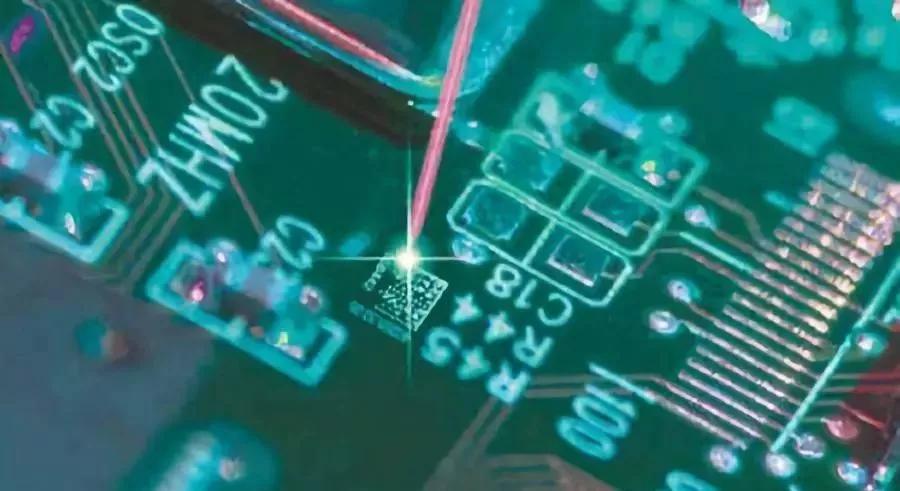

At present, laser processing has been widely used in laser marking, laser drilling, laser cutting and welding, material surface modification, laser rapid prototyping, laser composite processing and so on. In the manufacturing process of various components of smartphones, laser processing technology can be seen everywhere, such as mobile phone casing cutting, marking, welding, motherboard manufacturing, keyboard chip marking, engraving and punching of earphones, earphones, and accessories, etc.

In the marking process, fiber laser marking machines are generally used to mark relevant information. Although in many micromachining applications, we can use nanosecond laser marking machine to achieve, but there are still some shortcomings in the degree of refinement. The main reason is that the use of such laser equipment for micro-machined marking of mobile phones can easily impart more heat to mobile phone-related delicate products, resulting in melting, cracking, changes in surface composition and other harmful side effects.

However, with today's picosecond laser marking machines, it is possible to achieve true heat-free processing in the refined marking of mobile phones. In the actual marking process, picosecond laser equipment can be used to achieve high-speed, high-quality fine marking on mobile phone related products, while nanosecond laser equipment is often difficult to achieve the same quality, and is prone to various defects. A number of related issues arise from the partial heating of the marked surface that can result from long nanosecond pulses, including edge bumps, melting, chipping, and substrate cracking or damage.

Picosecond Laser Equipment

In addition to avoiding thermally related defects, utilizing today's picosecond laser equipment can also improve the efficiency of processing. The use of other marking equipment for fine processing of mobile phone-related parts requires long interaction times, which leads to more energy wastage, so the heat causes melting and also spreads rapidly in the area of processing modification. On the other hand, the picosecond laser device has a very short interaction time, and almost all the energy is directly applied to the marked mobile phone parts and related products through the laser pulse, which realizes instant laser ablation and has a high processing efficiency. .