Time:2021-07-17

Read volume:890

Share:

The plastic welding process has always been a pain point in the plastics industry. The traditional plastic bonding method has certain limitations, such as poor welding quality, low production efficiency, difficulty in welding complex shapes, serious environmental pollution, short life, follow-up processing and other problems. These questions have been plaguing people in the industry for a long time.

In recent years, Huazhuo Technology, as the first enterprise specialized in plastic laser welding in China, has successfully solved such problems by vigorously promoting plastic laser welding.

The welding objects for plastic laser welding are thermoplastics. The principle of welding is shown in the figure below, specifically: under the action of pressure, the upper and lower layers are bonded together; the laser beam passes through the upper transparent material and is then absorbed by the lower material. The laser energy is absorbed to increase the temperature of the lower layer material, melting the upper layer and the plastics in the lower layer, and through molecular reconstruction of the upper and lower layers of the material, a welding seam is formed.

Schematic diagram of plastic laser welding

In the lighting industry, most plastics are combined with viscose as the main method, but there are many problems:

1. The adhesive strength is low, the precision is low, the air tightness is poor, and it is difficult to meet the requirements of waterproofing

2. Manual production has low production efficiency and high labor costs

3. The glue is easy to age, and it is difficult to pass the thermal shock test

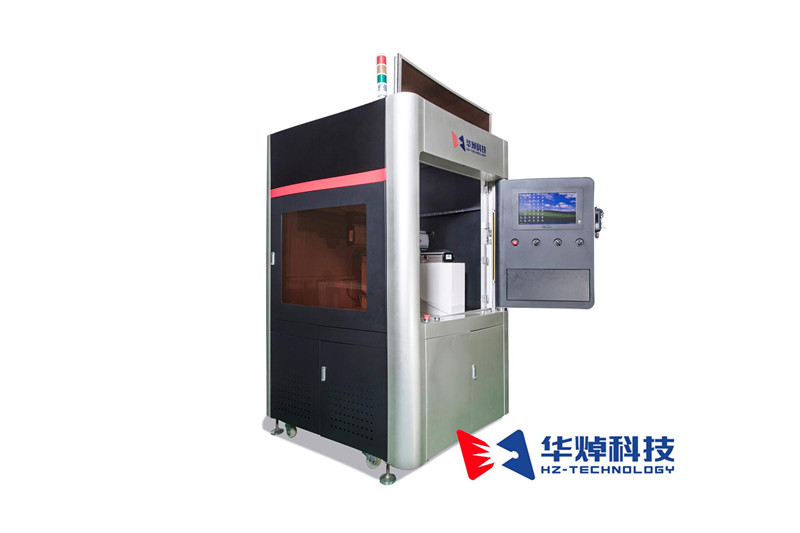

Facing so many problems in the lighting industry, Huazhuo Technology has creatively developed a three-axis plastic laser welding machine for the lighting industry, which has successfully solved the difficulties and pain points of the lighting industry.

Huazhuo's revolutionary product - three-axis plastic welding machine

Transparent plastic welding case: underwater lighting welding

Underwater lighting is a lighting fixture for underwater viewing, decoration, and task lighting. Due to the harsh working environment of underwater lamps and lanterns, long-term immersion in water also needs to experience the test of high temperature in summer and severe cold in winter, especially after the water freezes in winter, the test of lamps is particularly prominent. Therefore, underwater lamps and other lamps need to meet the ultra-high requirements of sealing, mechanical shock resistance, corrosion resistance, high temperature resistance, low temperature resistance and electrical performance.

In order to meet the above requirements, the lamps previously produced by Huazhuo Technology's customers need to be sealed with double sealing rings, then glued and sealed, and finally welded with ultrasonic waves. In the whole welding process, the production efficiency is low and the defective products are high. After understanding the customer's problem, the three-axis plastic laser welding machine developed by Huazhuo Technology for the customer, and the welded lamps have successfully passed the customer's stringent tests. This greatly improves the production efficiency of customers, and also greatly saves production costs for customers.